The best Side of DTF Transfers

The best Side of DTF Transfers

Blog Article

retain the silica gel pack saved along with your unused UltraColor Max transfers to help keep dampness faraway from transfers

in the event you've just lately bought your own home or never ever applied with the STAR profit, sign up—chances are you'll help you save hundreds yearly!

following printing, a powdered adhesive is placed on the print while it’s nonetheless soaked. The movie is then cured within an oven or heat press, solidifying the adhesive.

Additionally, be sure to use higher-good quality elements and maybe even conduct a take a look at press with an additional transfer on a small location in advance of applying a bigger structure to be certain suitable temperature, pressure, and transfer high-quality.

Now that we understand what DTF heat transfers are, Permit’s take a look at the advantages they offer for your small business.

This suggests it is possible to keep your stock lean and prevent the risk of overstocking or understocking. DTF heat transfers also permit you to provide a wider variety of goods while not having to spend money on a big inventory upfront.

the method commences with developing a electronic layout that is certainly printed on to the film applying DTF materials. superior-top quality inks ensure vivid shades and intricate particulars are captured over the movie.

Yet another main advantage of DTF warmth transfers is the chance to print whole-color layouts. standard monitor printing is restricted to a certain variety of colors, which can help it become tricky to accomplish advanced or in-depth patterns.

6. submit-urgent Care: To ensure the longevity of your print, it’s proposed that The material be allowed to awesome entirely right before dealing with. Also, pursuing the treatment instructions for that printed cloth should help preserve the vibrancy and durability of the look.

From scaled-down portions and comprehensive coloration printing to better inventory administration and more rapidly turnaround periods, Direct-to-film will help you streamline your operations and transform your base line.

Yellowing of adhesive or waffle texture around the copyright is feasible and normal; this will not have an effect on software.

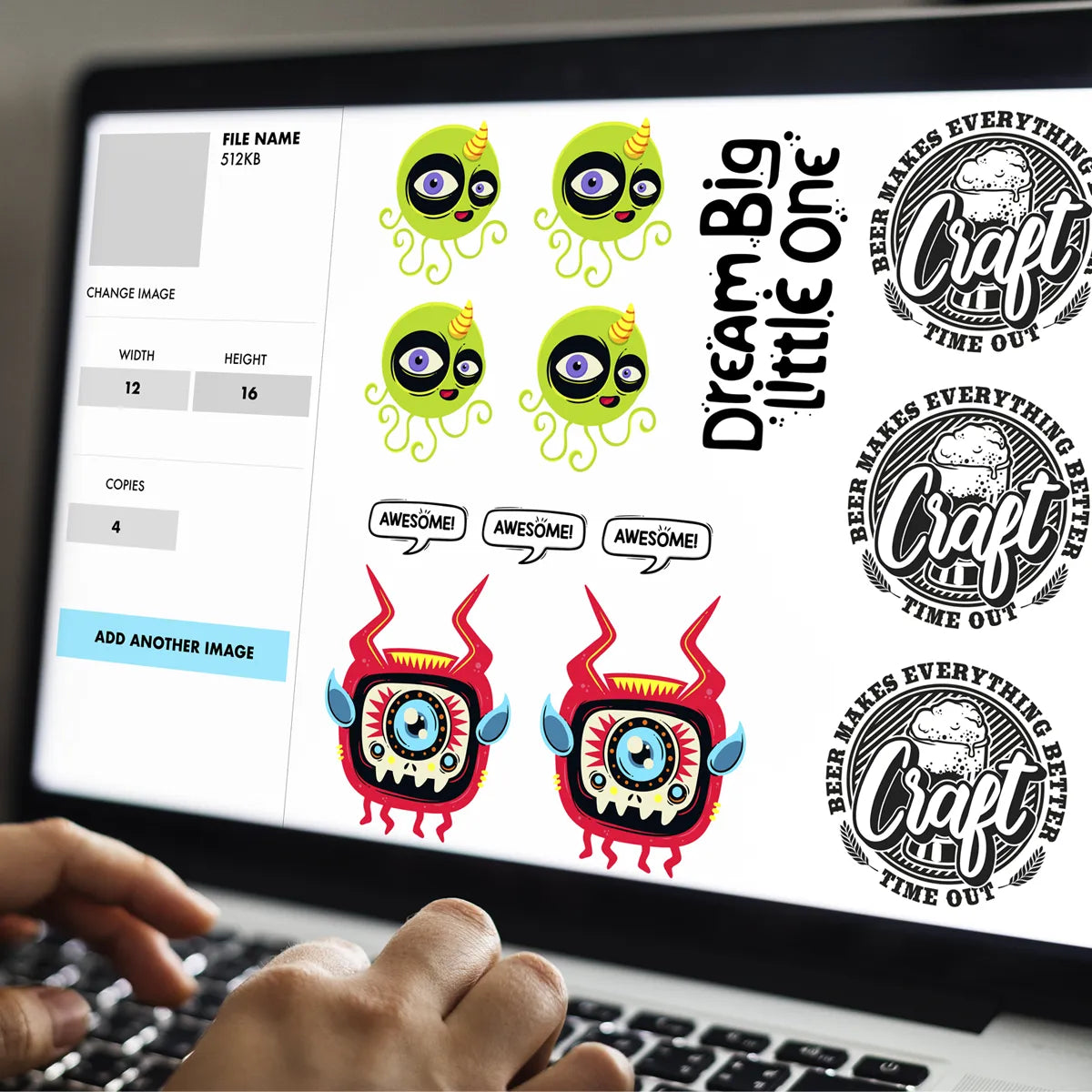

Upload: Next, you might add your structure; decide on the suitable transfer sheet dimension together with printed structure dimension in read more inches (if a specific design dimensions is required); point out the amount of transfers required; and specify your garment sort/shade. If you need an exact reorder, remember to let's understand that at the same time.

This will help you produce a standing for good quality and trustworthiness, which can lead to additional repeat enterprise and referrals.

Heat push: you will require a heat press to apply your DTF transfer for your garment. be sure your warmth press is suitable with DTF transfers and has the appropriate temperature and pressure options.

Report this page